It is the best technology on soldering for gas welding torch, soldering gun or electrical tweezers, able of joining at the lowest possible temperature (180°C) any metal. WHITE METALS: antimony, zamak, babbitt, aluminum, pewter, brass, lead, tin, zinc, etc. NON FERROUS: copper, bronze, brass, german silver (alpacca), nickel, silver, gold, etc. FERROUS: steel, cast iron, alloyed steels, etc. It is the best technology on soldering for gas welding torch, soldering gun or electrical tweezers, able of joining at the lowest possible temperature (180°C) any metal. WHITE METALS: antimony, zamak, babbitt, aluminum, pewter, brass, lead, tin, zinc, etc. NON FERROUS: copper, bronze, brass, german silver (alpacca), nickel, silver, gold, etc. FERROUS: steel, cast iron, alloyed steels, etc.

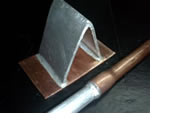

It also joins DISSIMILAR METALS such as: zamak/bronze, aluminum/copper, stainless steel/brass, steel/aluminum, german silver/stainless, etc.

PROCEDURE: Clean carefully the surfaces to join; for thick joints of more than 1/8”, bevel each side. First, you must preheat for a couple seconds the base metal with a small fuse and a slightly fuel. Then, apply FLUX AL50, and start raking the welding spread with flux towards the base metal, so, the welding melts with indirect heat (the heat transferred to the piece).

Do not over heat the welding or the flux and work at the lowest possible temperature, and do not touch the flux with the flame if possible. This must be in a yellow color during the soldering process, and it is recommended to solder with either soldering gun or electrical tweezers. Joints must be tinned on each of the parts to join and after that, solder. As a result, you can see a better adhesion and a higher resistance level on the joint.

TECHNICAL APPLICATIONS: IRON WORK INDUSTRIES such as: buckles, belts, adornments, jeweler’s shop, pre-Columbian replicas, fantasy dies, shields, buttons, medals, trophies, etc. AUTOMOTIVE INDUSTRY such as: carburetors, sheets, handles, cranks, mirror hoops, pinions, bombs and thermo forms plates, extruded or injected in zamac or antimony; radiators made of copper or aluminum. On chromed or nickel-plated pieces, the metallic covering is not damaged. METALWORKING INDUSTRY: Frameworks, engines, bombs, propellers made of Zamac/Antimony/Aluminium; dies of molten Zinc, anti-friction metals made of Babbitt; types of press, linotypes, monotypes, plates in lead from the press industry, musical instruments, etc. REFRIGERATION AND AIR CONDITIONING: Condensers, evaporating, refrigerators, etc.

TECHNICAL CHARACTERISTICS: Welding of great fluidity and penetration due to capillarity. Adhesion at a low temperature. It is way better than the conventional Tin-Lead welding, for being stainless and non toxic, keeping the welding always shining. Besides, it leaves more resistant joints with more elasticity to support vibration. Fine fluidity welding at low temperature.

It is Ideal for soldering with a gas welding torch Gas-Air or with an electrical tweezers on hard to warm-up joints (such as outside copper pipelines) due to its low melting point at 220°C (430°F).

OUTSTANDING CHARACTERISTICS: Joins almost any metal the lowest possible temperature, 180°C (360°F); it is possible to solder the following: Lead, Zinc, Tin, without deforming them, besides being possible to use it with a soldering gun. Outstanding resistance and adherence, 21.000 PSI. Joins dissimilar metals. Excellent moisturizer, fluidity and capillarity. Oxide resistant, excellent elasticity and wide electrical conductivity. This alloy exceeds the existing alloys.

Presentation: Rods 1/16”, 3/32”, 18”x18” long or continuous wire.

|