We offer two kinds of welding equipment. One of those is the ELECTRIC PLIERS that finds the heat on the place to weld. It works with current and is flame less, reducing the risk of turning fire on. It is suggested for soldering between 150°C and 350°C.

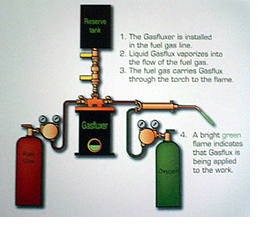

The other is GASFLUX equipment, capable of turning the liquid flux into gas, installed on the gas line and comes out with the flame, placing it directly on the welding point.

ELECTRIC PLIERS FOR WELDING

USES: The new Electric pliers, RIDGID RT-100 model, uses the new electric resistance warming-up technology, made for welding with no flame. Designed for soft soldering 1/4" - 1 1/2" Copper Tube. It welds any kind of copper, aluminum, steel pipe. Specially designed for repair and renovation jobs. USES: The new Electric pliers, RIDGID RT-100 model, uses the new electric resistance warming-up technology, made for welding with no flame. Designed for soft soldering 1/4" - 1 1/2" Copper Tube. It welds any kind of copper, aluminum, steel pipe. Specially designed for repair and renovation jobs.

CHARACTERISTICS: The electric pliers, flame free, it is a safe model, easy to use; ideal to get into tiny places with no risk of burning the parts next to it. Its small size makes it easier to use it, applying the exact quantity of heat, saving weld and time, optimizing the join quality. Six feet of cable. Built-in handle and cord wrap.

APPLICATIONS: This product can be used for all kind of soldering such as: Tin-Silver, Tin-Lead, Tin-Antimony, Aluminum-Silver, AL.50, SnAg. 95/5, etc. Copper, Aluminum, Bronze, Steel, etc. The maximum temperature this product can reach is 400°C (745°F) in 20 seconds.

Ideal for welding the following: refrigeration, air conditioning, sanitary, hydraulic and plumbing.

PROCEDURE: Clean the parts that are about to be joined, add the flux on the base metal and on the weld, turn the machine on and hold with the carbon tweezers the part that is going to be joined. Move the weld closer or make preformed rings on the join; take back the tweezers and turn the machine off when the weld had melted. You will be able to see that the resulting joins are perfect.

TECHNICAL CHARACTERISTICS:

Maximum temperature…………….400°C (745°f)

Warming time………………….. .....5 to 25 seconds

Machine size……………………......5”x10”x14”

Pipe capacity…………………....…..3/8” to 11/2”

Voltage………………………………115V, 15Am. and 220V

Weight………………………….……10,4Kg

Wire Length…………………………1, 8 Meter.

GASFLUX- THE FLUX IN THE FLAME

Excellent technology that saves time and money, leaving the welds in the best conditions ever (silver and bronze welds) with the GASFLUX process that carries the flux through the torch to the flame. Excellent technology that saves time and money, leaving the welds in the best conditions ever (silver and bronze welds) with the GASFLUX process that carries the flux through the torch to the flame.

A dispenser that contains a liquid flux which is installed in the combustible gas line, mixing the flux steam with the combustible gas, making the flux to get to the preheating place through the flame, keeping welding areas always protected for a perfect joint.

Advantages: Excellent technology that saves time and money, leaving the welds in perfect conditions (brazing alloys and bronze welds), with the GASFLUX process which carries the flux within the flame, keeping the welding areas always protected, for a perfect join. The following advantages stand out:

REDUCES COSTS IN A 40%: The GASFLUX process allows a faster welding with a better quality. In addition, the cleaning process is deleted, the consume of the weld is reduced due to its efficient output, the covered rods, powders and traditional paste made fluxes are disposed, avoiding any kind of contamination and oxidation leaving clean welds.

IDEAL JOINTS: Brazing alloys and bronze welds flow a lot better and faster, leaving even, straight, clean and pore free joints. The GASFLUX, applied in an even way, avoids glassy wastes which are left by conventional fluxes, saving time on cleaning and production.

HIGH PRODUCTIVITY: Soldering irons perform high quality jobs and outstanding appearance in a short time. GASFLUX allows producing more joints per hour with a minimum of rejects improving the operator/company welfare.

PROPERTIES: GASFLUX is a non contaminant flux, which does not oxidize or produces smog such as traditional fluxes, which contain fluoride. Does not leaves glassy wastes after welding, leaving the metal clean with no stains or burns.

APPLICATIONS: Air conditioning, bicycles, refrigeration, transformers, metallic furniture, automotive industries, assembles of tungsten tools, industrial filters, etc, or any kind of joint that requires brazing alloys and bronze welds.

OPERATION: The operation requires of just 4 minutes.

Connect the GASFLUX MACHINE to the fuel gas line, anyone you are using. Supply the volatile liquid flux in the reserve deposit and adjust the valve so you can use the exact quantity of the flux for the work you are performing. Turn the welding torch and a bright green flame indicates that GASFLUX is being applied to the work. Once the valve is adjusted, it does not need to be regulated.

|